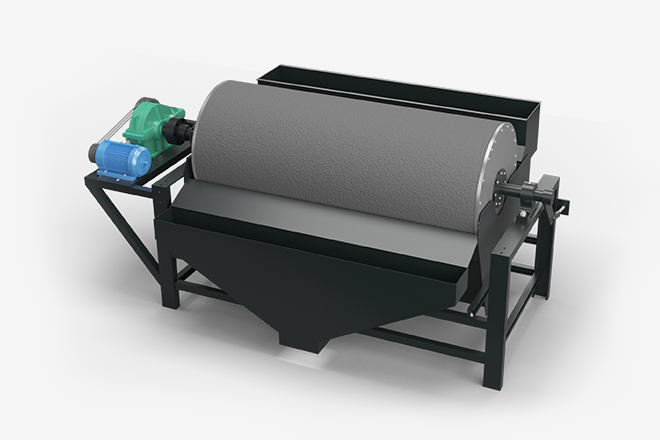

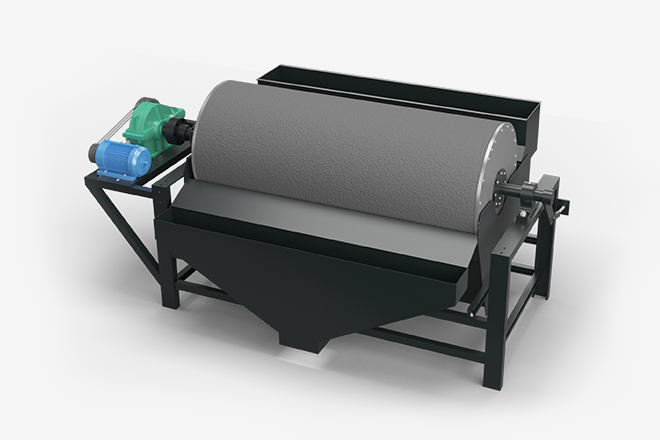

Magnetic separator---according to the different magnetic properties of minerals, the separation of materials with strong, medium or weak magnetic properties, different minerals are subjected to different forces in the magnetic field of the magnetic separator, thus being separated.

The magnetic separator is suitable for wet magnetic separation of materials with a particle size of less than 3 mm, such as magnetite, pyrrhotite, roasted ore, ilmenite, etc. It is also used for iron removal and purification of materials such as coal, non-metallic minerals, building materials, quartz, feldspar, kaolin, etc. it can also be used for wastewater treatment in steel plants and power plants, purification of contaminated chemical raw materials.

Magnetic separators use magnetic fields to separate magnetic and non-magnetic materials. When materials pass through the magnetic separator, magnetic particles (such as magnetite) are adsorbed to the surface of the magnetic roller or magnetic system under the action of the magnetic field, and non-magnetic particles (such as quartz and feldspar) fall along natural trajectories because they are not affected by magnetic force, thereby achieving separation.

| Model |

Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

| Model | Feeding size (mm) |

Processing capacity (t/h) |

| CTB6012 | 2-0 | 10-20 |

| CTB6018 | 2-0 | 15-30 |

| CTB7518 | 2-0 | 20-45 |

| CTB9018 | 3-0 | 40-60 |

| CTB9021 | 3-0 | 45-60 |

| CTB9024 | 3-0 | 45-70 |

| CTB1018 | 3-0 | 50-75 |

| CTB1021 | 3-0 | 50-100 |

| CTB1024 | 3-0 | 60-120 |

| CTB1218 | 3-0 | 80-140 |

| CTB1224 | 3-0 | 85-180 |

| CTB1230 | 3-0 | 100-180 |

| CTB1530 | 3-0 | 170-280 |

Online Chat

Scheme Determination

Solution Design

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production