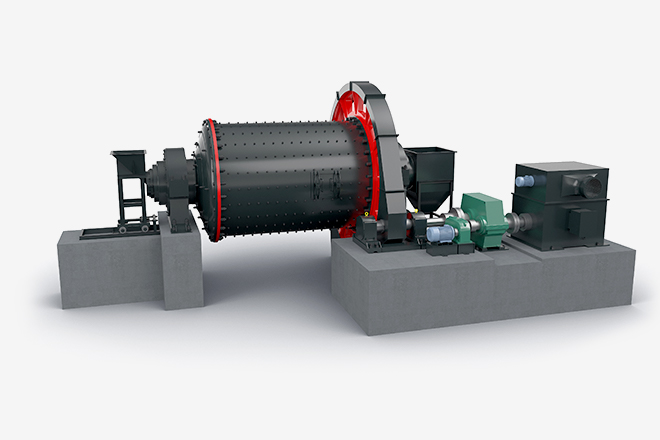

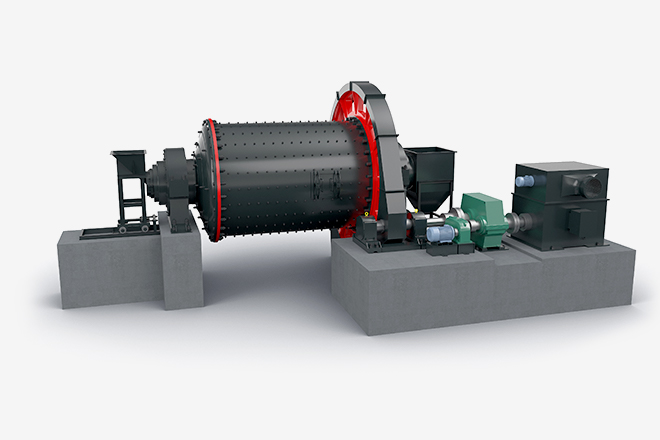

Ball mill is a mineral processing equipment used to grind and crush materials in the mineral processing process. Since the grinding medium of the ball mill is steel balls, that is to say, the ball mill grinds and crushes materials through steel balls, it is called a ball mill. The ball mill is a key equipment for crushing materials after they are crushed.

Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and non-ferrous metal beneficiation, glass and ceramics and other production industries.

Ball mill is a commonly used ore grinding equipment. Its working principle is to grind large pieces of material into fine powder by impacting, squeezing and grinding the material through the rotating cylinder and the internal grinding medium (such as steel balls).

| Model | Cylinder | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

Main Motor (KW) |

|

| Diameter (mm) | Length (mm) | |||||

| MQG-1557 | 1500 | 5700 | 8.5 | 12 | 28 | 130 |

| MQG-1564 | 1500 | 6400 | 9.6 | 13 | 28 | 155 |

| MQG-1864 | 1830 | 6400 | 15 | 20 | 23.8 | 210 |

| MQG-1870 | 1830 | 7000 | 16 | 22 | 23.8 | 245 |

| MQG-1880 | 1830 | 8000 | 18.8 | 26 | 23.8 | 280 |

| MQG-2170 | 2100 | 7000 | 22 | 30 | 24.1 | 320 |

| MQG-2175 | 2100 | 7500 | 23.5 | 33 | 24.1 | 355 |

| MQG-2265 | 2200 | 6500 | 22 | 35 | 21.7 | 380 |

| MQG-2270 | 2200 | 7000 | 23.8 | 38 | 21.7 | 380 |

| MQG-2275 | 2200 | 7500 | 25.5 | 42 | 21.7 | 450 |

| MQG-2470 | 2400 | 7000 | 28 | 52 | 21.7 | 570 |

| MQG-2480 | 2400 | 8000 | 32 | 60 | 21.5 | 630 |

| MQG-2750 | 2700 | 5000 | 25.8 | 54 | 20.7 | 630 |

| MQG-2760 | 2700 | 6000 | 31 | 65 | 20.6 | 710 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Effective Volume (m³) |

Max.Ball Loading (t) |

Speed (r/min) |

| MQG-1557 | 8.5 | 12 | 28 |

| MQG-1564 | 9.6 | 13 | 28 |

| MQG-1864 | 15 | 20 | 23.8 |

| MQG-1870 | 16 | 22 | 23.8 |

| MQG-1880 | 18.8 | 26 | 23.8 |

| MQG-2170 | 22 | 30 | 24.1 |

| MQG-2175 | 23.5 | 33 | 24.1 |

| MQG-2265 | 22 | 35 | 21.7 |

| MQG-2270 | 23.8 | 38 | 21.7 |

| MQG-2275 | 25.5 | 42 | 21.7 |

| MQG-2470 | 28 | 52 | 21.7 |

| MQG-2480 | 32 | 60 | 21.5 |

| MQG-2750 | 25.8 | 54 | 20.7 |

| MQG-2760 | 31 | 65 | 20.6 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Online Chat

Scheme Determination

Solution Design

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production