According to the difference in the chemical properties of the mineral surface (hydrophilicity, water buoyancy), after being treated with flotation agents, useful minerals (positive flotation method)/useless impurities (reverse flotation method) are selectively attached to the bubbles to achieve the purpose of sorting. This method is chemical ore dressing.

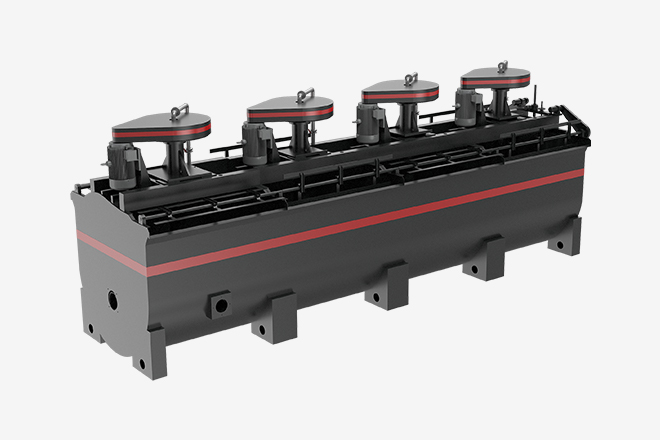

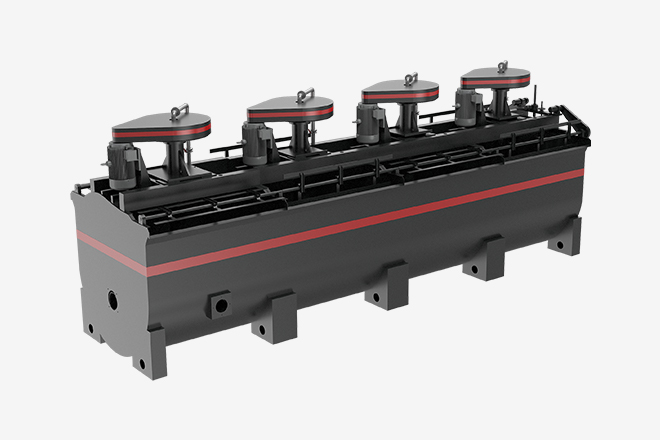

Flotation machines are mainly used to sort non-ferrous metals, ferrous metals, precious metals, non-metallic mineral.metal minerals such as gold, silver, copper, lead, zinc, molybdenum, nickel, and aluminum. It can also be used for the sorting of ferrous metals and non-metals (such as graphite and apatite).

The machine is driven by a V-belt drive of an electric motor to drive the impeller to rotate, generating a centrifugal effect to form a negative pressure. On the one hand, it inhales sufficient air to mix with the ore pulp, and on the other hand, it stirs the ore pulp and mixes with the drug, while refining the foam, so that the minerals adhere to the foam, float to the surface of the ore pulp, and then form mineralized foam. Adjust the gate height to control the liquid level so that the useful foam is scraped out by the scraper.

| Model | XCF-1 | XCF-2 | XCF-3 | XCF-4 | XCF-8 | XCF-16 | XCF-24 | XCF-38 | |

| Dimensions | Length(mm) | 1000 | 1300 | 1600 | 1800 | 2200 | 2800 | 3100 | 3600 |

| Width(mm) | 1000 | 1300 | 1600 | 1800 | 2200 | 2800 | 3100 | 3600 | |

| Height(mm) | 1100 | 1250 | 1400 | 1500 | 1950 | 2400 | 10819 | 3400 | |

| Single Effective Weight(t) | 1.2 | 1.7 | 2.3 | 2.7 | 3.9 | 6.6 | 8.0 | 16.8 | |

| Effective cubage(m³) | 1 | 2 | 3 | 4 | 8 | 16 | 24 | 38 | |

| Production Capacity (m³/min) | 0.2—1 | 0.4—2 | 0.6—3 | 1.2—4 | 3—8 | 4—16 | 4—24 | 10—38 | |

| Main shaft motor | Model | Y132M2-6 | Y160M-6 | Y160L-6 | Y180L-6 | Y200L2-6 | Y280S-8 | Y280S-8 | Y280S-6 |

| Power(kw) | 5.5 | 7.5 | 11 | 15 | 22 | 37 | 37 | 45 | |

| Impeller | Rotate speed(r/min) | 960 | 970 | 970 | 970 | 970 | 740 | 740 | 980 |

| Diameter(mm) | 400 | 460 | 540 | 620 | 720 | 860 | 950 | — | |

| Height(mm) | 155 | 175 | 207 | 247 | 321 | 349 | — | — | |

| Rotate speed(r/min) | 358 | 331 | 266 | 215 | 185 | 160 | 153 | — | |

| Circular velocity(m/s) | 7.5 | 7.5 | 7.5 | 7 | 6.97 | 7.6 | 7.6 | 7.4 | |

| loam board motor | Model | Y90S-4 | Y90S-4 | Y90L-4 | Y90L-4 | Y90L-4 | Y90L-4 | Y90L-4 | Y90L-4 |

| Power(kw) | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Rotate speed(r/min) | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| loam board | Rotate speed(r/min) | 18 | 18 | 16 | 16 | 16 | 16 | 16 | 16 |

| Diameter(mm) | 500 | 500 | 580 | 600 | 600 | 700 | 700 | 700 | |

| Wind pressure of fan (kpa) | ≥12.6 | ≥14.7 | ≥19.8 | ≥19.8 | ≥21.6 | ≥25.5 | ≥30.4 | ≥34.3 | |

| Max. air injection amount(m³.min) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Model | Effective cubage(m³) | Production Capacity (m³/min) |

| XCF-1 | 1 | 0.2-1 |

| XCF-2 | 2 | 0.4-2 |

| XCF-3 | 3 | 0.6-3 |

| XCF-4 | 4 | 1.2-4 |

| XCF-8 | 8 | 3-8 |

| XCF-16 | 16 | 4-16 |

| XCF-24 | 24 | 4-24 |

| XCF-38 | 38 | 10-38 |

Online Chat

Scheme Determination

Solution Design

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production