NEWS&ENVENTS

News >News DetailsDevelopment and Efficiency Improvement of Ball Mill

1) Ensure appropriate rotation speed of the drum

If the speed is slow, the centrifugal force will be small, friction also will be small, grinding body cannot rise with tube wall, also is impossible to do lifting and throwing movement. On the contrary, if the speed is fast, centrifugal force will be big, friction also will be big, grinding body clings with tube body wall, also cannot do lifting and throwing movement. Without lifting and throwing movement, grinding body will not do collision on raw materials, and only grinding will reduce efficiency, so the over slow or fast speed of tube body is not desirable.

2) Select suitable internal linings and grinding media

Lining has two roles, on the one hand, protects the cylinder from being worn, on the other hand, and prevents material to contact with the iron to avoid pollution. In general, more wear-resistant can be selected as ball mill liners, to guarantee durability. In order to increase the effective volume, on the premise of the same formula and feeding amount, you should choose grinding media with reasonable ratio, high density, high hardness, to reduce grinding time, while reduce the rate of wear of the grinding media.

3) Make the appropriate proportion of materials, balls and water

Loading capacity of the grinding media has a major impact on the efficiency improvement of ball mill. If the loading capacity is too small, materials impacts and grinding will be small, while excessive load reduces feeding, grinding interaction will be increased. The proportion of material and water should be appropriate, eventually see the water rate of mud and liquidity to set water yield. In general, the appropriate proportion of materials, balls and water should be 1:18:6, but total volume after mixing material, ball and water should be about 90% of the effective volume. In addition, you can also adjust the formula, reduce the kinds of rigid materials, control maximum diameter of coarse granular materials, select appropriate additives and other methods to improve the efficiency for ball mill.

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

Hot product

-

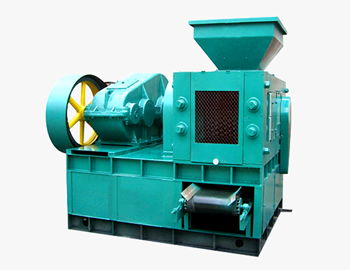

Hydraulic briquette machine

Hydraulic ball press machine can be used for pressing all kinds of ore powder -

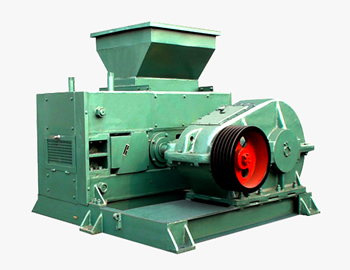

Coal briquette press machine

In recent decades, the coal briquette plants continue the low-level redundant construction. -

Energy-saving briquette machine

As for energy-saving briquette machine, the electromagnetic variable-speed motor will