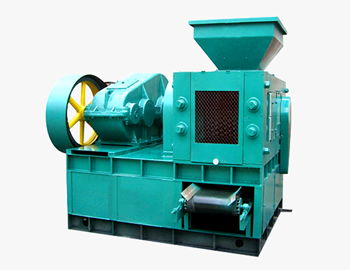

Hydraulic briquette machine

Home>Products center > Briquette machine > Details

Hydraulic briquette machine

Introduction to Hydraulic briquetting machine

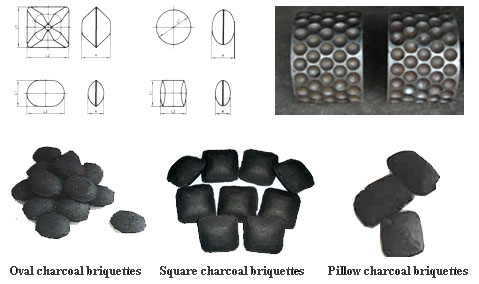

Hydraulic briquetting machine or hydraulic briquette machine can be used for pressing all kinds of ore powder, metal powder, coal powder, coke powder and other materials. Due to the forced squeezing of the rollers, the final products have such features as high density, high strength and high hardness. In addition, the rollers of Fote hydraulic briquetting machine are made of 650mn hard materials with excellent wear-resisting performance, thus effectively improving the service life of the rollers.

Application Range of Hydraulic briquetting machine

1. Hydraulic briquetting machine is a new generation of product developed by making full use of all kinds of mature technologies and basing on the domestic and foreign development direction of the ball press machine industry.

.jpg)

2. The rollers of hydraulic briquette machine are casted with wear-resisting alloy, the bearings adopt rolling mill bearings and the hydraulic system is provided by large manufacturing companies.

3. The practical application of hydraulic briquette machine is very wide, and it can be used for molding all kinds of materials and powdery materials, such as cryolite, aluminum oxide, fertilizer, magnesium powder, bauxite, aluminum ash as well as powdery materials in ferrous metal industry and refractory industry.

Working Principle of Hydraulic briquetting machine

As for this series of hydraulic briquetting machine, the power is transmitted to the two rollers at the same time by the reducer to make them rotating at the opposite direction. In the rotating process of the two rollers, the materials will evenly go into the pellet mould of the rollers. With the rotation of the rollers, the pressure on the materials will change. When the materials move to the linear contact point of the two rollers, the pressure on the materials will reach a peak. Under the huge linear pressure, the materials will be pressed form powder to final pellet by hydraulic briquette machine.

Technical Data

| Model | Roll diameter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t/h) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

-

How to Choose a Reliable Ball Mill Manufacturer?

[30/05/2017]

-

Research and Development is Valuable for Ball Mills

[28/11/2014]

-

Hammer Crusher Advances Fast in Information Age

[25/11/2014]