Energy-saving briquette machine

Home>Products center > Briquette machine > Details

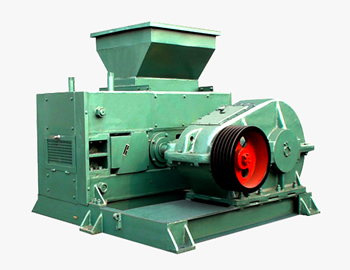

Energy-saving briquette machine

Power: 7.5-30kw

Capacity: 4-18TPH

Materials: Coal power, iron powder, coking coal, aluminum powder, iron slag, oxide scale, carbon powder, slag, gypsum, sludge, kaolin, clay, activated carbon, etc.

Introduction to energy-saving briquette machine

As for energy-saving briquette machine or energy-saving briquetting machine, the electromagnetic variable-speed motor will provide power for the electric motor and through belt pulley and cylindrical gear reducer, the power will be transmitted to driving shaft through the rod pin coupling. The driving shaft and driven shaft are ensured to operate synchronously through open gear. Behind the driven bearing pedestal, there is hydraulic equipment.

.jpg)

Working principle of energy-saving briquette machine

The hydraulic protective device of Fote energy-saving briquetting machine uses hydraulic pump to inject the high-pressure oil into the hydraulic cylinder to make the piston have axial displacement. The front connecting head of the piston rod is pressure onto the bearing pedestal to satisfy the pressure requirement for production. When there are too many materials between the two rollers or metal block goes into the rollers, the hydraulic cylinder piston rod of energy-saving briquetting machine will pressed, and the hydraulic pump will stop, and the energy accumulator will have buffer action on the pressure change.

.jpg)

Features of energy-saving briquette machine

The overflow valve of energy-saving briquetting machine will start for oil return and the piston rod will have displacement to increase the gap between the two rollers, so that the hard materials will go through the rollers, and then the system pressure will resume to normal, this design can protect the roller from being damaged. According to the requirement for the press density, energy-saving briquette machine or energy-saving briquetting machine can be adjusted in pressure, so that the production process is mobile and flexible.

Energy-saving briquette machine is mainly composed of three parts: feeding part, transmission part and forming part.

.jpg)

Technical Data

| Model | Roll diameter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t/h) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

-

How to Choose a Reliable Ball Mill Manufacturer?

[30/05/2017]

-

Research and Development is Valuable for Ball Mills

[28/11/2014]

-

Hammer Crusher Advances Fast in Information Age

[25/11/2014]