The HPM series multi-cylinder cone crusher is designed for crushing high-hardness materials with strict particle shape requirements. It features a full range of models and includes the latest intelligent and Internet control systems.

| Model | Cavities | Max.Feeding Size(mm) | Minimum Discharging Size(mm) | Processing Capacity(t/h) | Speed(r/m) | Power(kW) |

| HPM200 | C1 | 185 | 19 | 150-250 | 750-1200 | 160 |

| C2 | 125 | 17 | 140-250 | |||

| C3 | 95 | 13 | 120-250 | |||

| F1 | 76 | 10 | 90-210 | |||

| F2 | 54 | 6 | 80-210 | |||

| F3 | 23 | 5 | 70-210 | |||

| F4 | 10 | 6 | 80-210 | |||

| HPM300 | C1 | 235 | 25 | 230-445 | 700-1200 | 220 |

| C2 | 211 | 19 | 200-445 | |||

| C3 | 150 | 17 | 180-445 | |||

| C4 | 107 | 13 | 150-445 | |||

| F1 | 77 | 10 | 115-260 | |||

| F2 | 53 | 8 | 110-260 | |||

| F3 | 22 | 6 | 105-260 | |||

| F4 | 25 | 6 | 105-260 | |||

| HPM400 | C1 | 299 | 30 | 315-630 | 700-1000 | 315 |

| C2 | 252 | 25 | 295-630 | |||

| C3 | 198 | 20 | 260-630 | |||

| C4 | 111 | 14 | 190-630 | |||

| F1 | 92 | 10 | 140-370 | |||

| F2 | 52 | 8 | 130-370 | |||

| F3 | 51 | 6 | 120-370 | |||

| F4 | 52 | 6 | 120-370 | |||

| HPM500 | C1 | 335 | 30 | 390-790 | 700-950 | 400 |

| C2 | 286 | 25 | 365-790 | |||

| C3 | 204 | 20 | 325-790 | |||

| C4 | 133 | 16 | 280-790 | |||

| F1 | 95 | 13 | 230-450 | |||

| F2 | 57 | 10 | 175-450 | |||

| F3 | 52 | 8 | 165-450 | |||

| F4 | 53 | 6 | 155-450 | |||

| HPM650 | C1 | 328 | 30 | 386-790 | 590-930 | 500 |

| C2 | 279 | 25 | 348-790 | |||

| C3 | 196 | 20 | 300-790 | |||

| F1 | 106 | 13 | 280-530 | |||

| F2 | 52 | 9 | 220-530 | |||

| HPM800 | C1 | 353 | 32 | 545-1100 | 700-950 | 630 |

| C2 | 297 | 32 | 545-1100 | |||

| C3 | 267 | 25 | 495-1100 | |||

| C4 | 219 | 16 | 385-1100 | |||

| F1 | 155 | 13 | 325-730 | |||

| F2 | 92 | 10 | 260-730 | |||

| F3 | 33 | 5 | 200-730 |

| Model | Cavities | Max.Feeding Size(mm) |

Processing Capacity(t/h) |

| HPM200 | C1 | 185 | 150-250 |

| C2 | 125 | 140-250 | |

| C3 | 95 | 120-250 | |

| F1 | 76 | 90-210 | |

| F2 | 54 | 80-210 | |

| F3 | 23 | 70-210 | |

| F4 | 10 | 80-210 | |

| HPM300 | C1 | 235 | 230-445 |

| C2 | 211 | 200-445 | |

| C3 | 150 | 180-445 | |

| C4 | 107 | 150-445 | |

| F1 | 77 | 115-260 | |

| F2 | 53 | 110-260 | |

| F3 | 22 | 105-260 | |

| F4 | 25 | 105-260 | |

| HPM400 | C1 | 299 | 315-630 |

| C2 | 252 | 295-630 | |

| C3 | 198 | 260-630 | |

| C4 | 111 | 190-630 | |

| F1 | 92 | 140-370 | |

| F2 | 52 | 130-370 | |

| F3 | 51 | 120-370 | |

| F4 | 52 | 120-370 | |

| HPM500 | C1 | 335 | 390-790 |

| C2 | 286 | 365-790 | |

| C3 | 204 | 325-790 | |

| C4 | 133 | 280-790 | |

| F1 | 95 | 230-450 | |

| F2 | 57 | 175-450 | |

| F3 | 52 | 165-450 | |

| F4 | 53 | 155-450 | |

| HPM650 | C1 | 328 | 386-790 |

| C2 | 279 | 348-790 | |

| C3 | 196 | 300-790 | |

| F1 | 106 | 280-530 | |

| F2 | 52 | 220-530 | |

| HPM800 | C1 | 353 | 545-1100 |

| C2 | 297 | 545-1100 | |

| C3 | 267 | 495-1100 | |

| C4 | 219 | 385-1100 | |

| F1 | 155 | 325-730 | |

| F2 | 92 | 260-730 | |

| F3 | 33 | 200-730 |

Online Chat

Scheme Determination

Solution Design

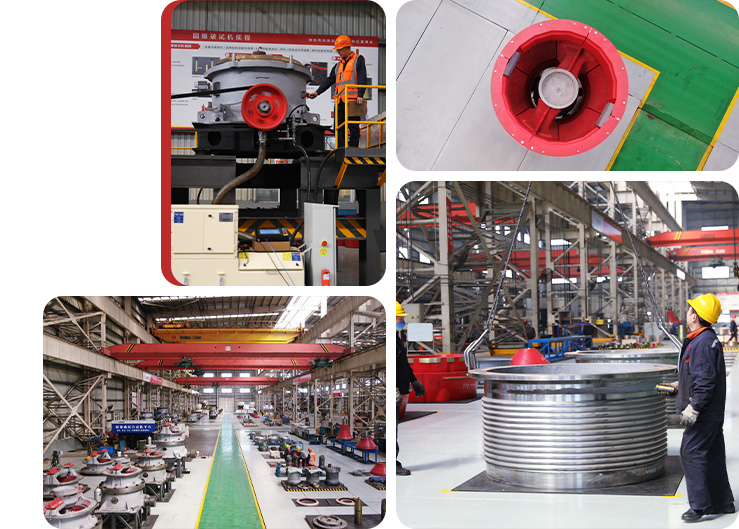

Products Manufacturing

Express Transportation

Installation Guidance

Fast Production