Sand maker

Home>Products center > Stone crushing machine >Details

Sand maker

Processing ability: 0.26–30 m3

Rotate speed: 200–530 r/min

Diameter: 240–850 mm

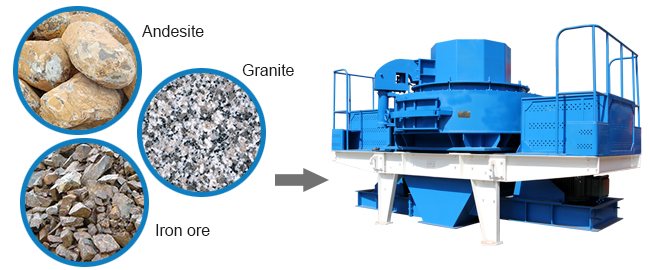

Applied material: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone.

The sand maker or VSI sand maker is suitable for the crushing and shaping of soft, medium hardness and extremely hard materials, such as various ores, cement, refractory materials, aluminum soil clinker, emery, glass raw materials, building stone and gold slag. Sand making machine or sand making machinery has high efficiency in the crushing of extremely hard and corrosion-resistance materials like silicon carbide and emery.

.jpg)

Application of sand maker

1. The manufacturing of artificial sand. There are various materials come in handy, such as river gravel, rocks (limestone, granite, basalt, diabase, etc.), ore tailings, stone chips and so on.

2. The production of construction aggregates, asphalt concrete, road pavement materials, bedding material, concrete aggregate and cement aggregate.

3. Production of manufactured sand and stone shaping in the engineering projects like water conservancy and hydropower, high-grade highways, expressways, high-speed rail, passenger dedicated lines, bridges, runways, municipal engineering and high-rise buildings.

4. Fine crushing of mining sector and material crushing of building materials, metallurgy, chemical industry, mining, refractory materials, cement and so on.

5. Production of high-purity materials like glass, quartz sand and others.

.jpg)

Performance characteristics of sand maker

1. Simple structure and low cost;

2. High efficiency and energy saving, high crushing efficiency;

3. Fote sand making machinery has functions of fine crushing and coarse grinding;

4. High passing rate of non-crushing materials and little influence of the material moisture. The moisture content of sand made by sand making machine or VSI sand maker can be up to 8%;

5. Crushing of medium hard and hard materials (such as corundum, sintered bauxite, etc);

6. Cubic shape of finished product and little iron pollution

7. Easy operation and maintenance

8. Low working noise

9. Light weight and diversified installation.

.jpg)

.jpg)

.jpg)

Parameter

| Model specification |

Max.feeding size (mm) |

Power (kw) |

Rotation speed of impeller (r/min) |

Capacity (t/h) |

Overall dimension (L×W×H) (mm) |

| FTM-06 | 35 | 2P 37-55KW | 2000-3000 | 10-30 | 2500×1620×2600 |

| FTM-07 | 45 | 4P 55-75KW | 1500-2500 | 20-55 | 2700×1760×2800 |

| Model | VSI 7611 | VSI 8518 | VSI 9526 | VSI 1140 | VSI 1145 | VSI 1150 | |

| Capacity (t/h) |

Feed both at center and sides | 80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Feed at center | 40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Max.feeding size (mm) |

Soft material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1150-1300 | 1150-1300 | 1150-1300 | |

| Motor power(kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall dimension(L×W×H)(mm) | 4100×2250×2300 | 4160×2320×2900 | 4560×2450×2830 | 5500×2700×3100 | 5500×2700×3100 | 5500×2700×3100 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

-

How to Choose a Reliable Ball Mill Manufacturer?

[30/05/2017]

-

Research and Development is Valuable for Ball Mills

[28/11/2014]

-

Hammer Crusher Advances Fast in Information Age

[25/11/2014]