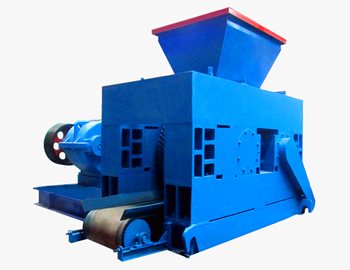

Dry powder briquette machine

Home>Products center > Briquette machine > Details

Dry powder briquette machine

Power: 37-55kw

Capacity: 1-18TPH

Application: Dry powder briquetting machine is widely used in refractory materials, powder plant, metallurgy, chemical industry, energy, transportation, heating and other industries.

Purpose of Dry Powder Briquette Machine

Dry powder briquette machine can be used for pressing coal power, iron powder, coke, aluminum power, scrap iron, sinter, carbon dust, powdered carbon, slag, gypsum, tailing, slurry, kaolin, active carbon and coke breeze in various industries such as refractory, power station, metallurgy, chemistry, energy, transportation and heating. The materials made and pressed by dry powder briquetting machine can save energy and protect the environment and are convenient for transportation, thus improving the utilization rate of waste materials and having excellent economic and social benefits.

Application of Dry Powder Briquette Machine

Dry powder briquette machine is mainly used for the pelleting of ferrous and non-ferrous metal ore powders, and the pellets can be directly fed into the furnace for smelting, thus improving their added value. All the waste material in the metallurgical industry need dry powder briquetting machine, such as fly ash, pool mud, scale cinder, steel slag, iron finemeal, aluminum ash and bementite powder.

Detailed technology of Dry Powder Briquette Machine

After being screened by sieving machine, the limestone smaller than 3mm will be sent into the dry powder briquetting machine for pressing and the ball pellet specification is 35mm*25mm*15mm. Of course, the dry powder briquette machine can be designed according to the specific requirement of the customers. The pellet density is 1.9-2.2g/cm³. After pressing and screening, the qualified pellet will go into the final products cabin for smelting.

Technical Data

| Model | Roll diameter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t/h) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

-

How to Choose a Reliable Ball Mill Manufacturer?

[30/05/2017]

-

Research and Development is Valuable for Ball Mills

[28/11/2014]

-

Hammer Crusher Advances Fast in Information Age

[25/11/2014]