NEWS&ENVENTS

News >News DetailsHow to Make Full Use of Hammer Head of Hammer Crusher?

The hammer head of hammer crusher is carrying the daunting mission every day by fighting hand-to-hand with tough stone, so the hammer head with no matter what materials will be depleted quickly under this kind of intensity impact. Hammer crusher is commonly used crushing equipment widely used in mining, chemical industry, metallurgy, building materials, electric power industries, etc. The hammer head is a major quick-wear part, so the quality of hammer head has direct impact on the crushing efficiency of hammer crusher. Therefore, regular maintenance measures must be important, generally, good maintenance can save more money than purchasing new hammer head.

During working hours, the hammer head of hammer crusher must bear impact and shock from material, so long term used can make it damaged. Factors influencing the service life of hammerhead of hammer crusher are as follows.

1. Structural design and quality of hammer head

Structure design and geometric shape of hammer head has great impact on the mechanical properties and internal microstructure of heat-treatment hammer head. According to failure analysis of hammers with different materials, different degrees of impairment in internal or on surface of the hammer head is the main factor caused its break. Therefore, manufacturers must establish reasonable casting and heat treatment processes for hammer head production.

2. Technical parameter of hammer crusher

The technical parameters of Hammer Crusher will also affect the service life of hammer heads, especially the power and speed of the rotor, which are not only related to the crusher capacity, but also impact the hardening degree of hammer head.

3. The blockness and hardness of breaking material

The larger size the material is, the higher toughness the hammer head requires. Crusher model should be suitable for particle size of materials, because this will, to a certain extent, extend the service life of the hammer head.

4. The internal clearance adjustment of hammer crusher

The internal clearance of hammer crusher mainly refers to the clearance between rotor and counterattack plate, and the clearance between grate bars and hammer heads. The size of these gaps relates to whether there is aggregate near the security gate.

Interested in our machine? We'd love to hear from you! Leave us a message now for discount price. Our professional team will reply to you within one business day. Thank you so much and wish you a good day!

Product Categories

- Stone crushing machine

- Ore dressing machine

- Building materials equipment

- Powder making machine

- Dryer machine

- Mobile crushers

- Briquette machine

- Production line

- Cable recycling machine

- Scrap metal crusher

- Double-disk friction screw press

- Asbestos tile equipment

- Calcium silicate board machine

- Recommended products

Hot product

-

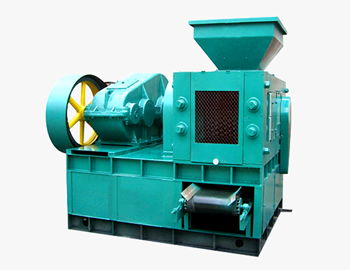

Hydraulic briquette machine

Hydraulic ball press machine can be used for pressing all kinds of ore powder -

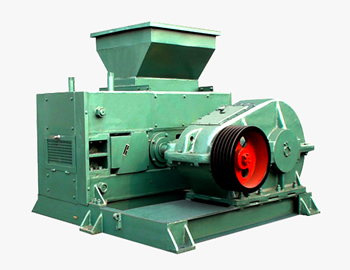

Coal briquette press machine

In recent decades, the coal briquette plants continue the low-level redundant construction. -

Energy-saving briquette machine

As for energy-saving briquette machine, the electromagnetic variable-speed motor will